Description:

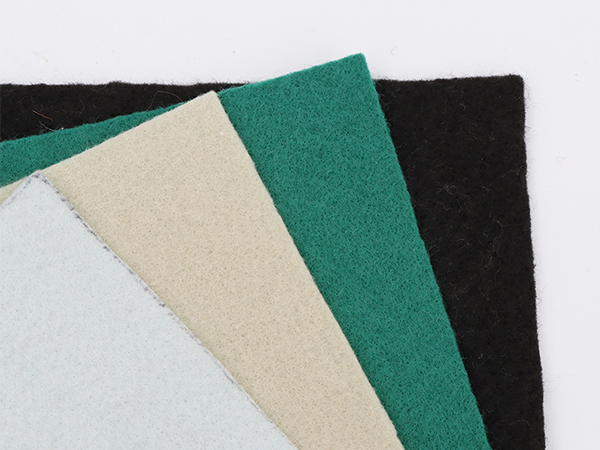

Filament Non woven Geotextile is Continuous Filament Needle punched non-woven Geotextile which made from Polyester, formed by the process of needle punching and thermally bounding, offers optimum performance per unit weight. Filament Non woven Geotextile provides effective and economical solution of separation, filtration, drainage, protection and reinforcement functions for engineering projects.

Product Features:

Filtration

when water passes from a fine-grained to a coarse grained layer, Non-woven Geotextiles can retain fine particles well. Such as when water flows from a sandy soil into a Geotextile wrapped gravel drain.

Separation

to separate two layers of soil with different physical properties, such as the separation of road gravel from soft sub-base materials.

Drainage

to drain liquid or gas from the plane of the fabric, which leads to draining or venting of the soil, such asthe gas vent layer in a landfill cap

Reinforcement

to improve the load bearing capacity of a specific soil structure, such as the reinforcement of a retaining wall.

Technical data sheet:

Test | Unit | YS10 | YS15 | YS20 | YS25 | YS30 | YS35 | YS40 | YS45 | YS50 | YS60 | YS80 | |

No. | Mass per square meter | g/m2 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 800 |

1 | weight variation | % | -6 | -6 | -6 | -5 | -5 | -5 | -5 | -4 | -4 | -4 | -4 |

2 | thickness | mm | 0.8 | 1.2 | 1.6 | 1.9 | 2.2 | 2.5 | 2.8 | 3.1 | 3.4 | 4.3 | 5.5 |

3 | width variation | % | -0.5 | ||||||||||

4 | Break Strength(M D adn XMD) | kN/m | 4.5 | 7.5 | 10.5 | 12.5 | 15 | 17.5 | 20.5 | 22.5 | 25 | 30 | 40 |

5 | Elongation Break | % | 40 ~80 | ||||||||||

6 | CBR Burst Strength≥ | kN/m | 0.8 | 1.4 | 1.8 | 2.2 | 2.6 | 3 | 3.5 | 4 | 4.7 | 5.5 | 7 |

7 | sieve size 090 | mm | 0.07 ~0.20 | ||||||||||

8 | Coefficient of Pemeability | cm/s | (1.0-9.9)X(10-1 ~10-3) | ||||||||||

9 | Tear Strength | kN/m | 0.14 | 0.21 | 0.28 | 0.35 | 0.42 | 0.49 | 0.56 | 0.63 | 0.7 | 0.82 | 1.1 |

Application:

To reinforce the backfill of retaining wall or to anchor the face plate of retaining wall. Build wrapped retaining walls or abutments.

Reinforcing flexible pavement, repairing cracks on the road and preventing reflective cracks on the road surface.

Increase the stability of gravel slope and reinforced soil to prevent soil erosion and freezing damage at low temperature.

The isolation layer between ballast and roadbed or between roadbed and soft ground.

The isolation layer between artificial fill, rockfill or material field and foundation, the isolation, filtration and reinforcement between different frozen soil layers.

The filter layer of the upper reaches of the initial ash storage dam or tailings dam, and the filter layer of the drainage system in the backfill of the retaining wall.

The filter layer around the drainage pipe or gravel drainage ditch.

The filters of water wells, relief wells or oblique pressure pipes in hydraulic engineering.

Geotextile isolation layer between highway, airport, railway slag and artificial rockfill and foundation.Vertical or horizontal drainage within the earth dam, buried in the soil to dissipate the pore water pressure.

Drainage behind impervious geomembrane or under concrete cover in earth dams or embankments.